How to Know When You Need a New Miter Saw Blade

Professional tile installers and structure pros hold that diamond blades are a very important component for a swell work. The capability and toughness of a diamond saw are vital to having sharp cuts in your tile and flooring material. The corking DC-250 tile saw or any other of the RUBI tile saws will provide smashing results when equipped with a reliable diamond blade. Before buying a new diamond bract, think that fabric cost, sharpness and durability are some of the most of import factors to consider in the tile installation process.

This commodity introduces some of the different types of blades available in the market and how each ane is a fit for certain tile formats and types.

[RELATED: Looking for a pinnacle rated tile saw? Know why the DC-250 tile saw is the pro's option]

Why Are They Called Diamond Blades?

Diamond blades consist of a steel core and diamond segments, which are fabricated past combining and sintering diamond crystals with different metals. Thesesintered metal-bonded diamond blades are the virtually common type of blade.The diamond pieces blended with the metals is what provides a durable and efficient blade saw. The diamond extrusions of the "teeth" volition work to grind through the material. The tougher the blade, the more than exposed these diamond pieces are, so they can generate a cleaner cut along harder materials.

RUBI Tools takes pride in their manufacturing process in lodge to provide a unique textile for sharper and neater cuts. The blade lifecycle is very of import and it is proportional to the bonding betwixt the steel and the metals. A hard bail generally means a longer duration of the bract, and that's something RUBI Tools emphasizes on. Proper care of these tile saw blades is important to extend their life up to the manufacturer's recommendation.

Uses and Applications of Diamond Blades

Diamond blades are circular shaped saws used for sawing and cut construction materials. Tile installers utilize these types of saws on remodeling or new construction projects, when they need to cut tile, concrete, porcelain and other materials. Diamond saw blades can exist used in wet or dry conditions, but remember that under the latter circumstance, information technology may generate lots of grit particles. When this happens, the user must article of clothing dust aspirators or deploy boosted tools to avert aspiring the dust. Other uses for diamond saw are: grooving, wafering, slotting, dicing, gang sawing, slicing, and rough cutting applications.

These types of saws are neat because they can minimize tile chipping, provide faster and reliable cut activity. Boosted benefits of using tile saw blades are that they volition reduce the amount of wasted material and reduced cutting racket.

How to Choose the Right Blade?

We know that you will expect for an efficient and long-lasting blade. It is hard to know how long a blade will terminal, as yous will use it to cutting different materials with unlike thickness. It will also depend on the care and maintenance of the bract. Here are some important factors that you lot should know before buying your new blade:

- Blades come in different types including segmented, continuous rim or turbo rim.

- The blade thickness will determine the cut'due south width.

- If you demand a blade to cut different materials, so you need to call up of the hardest materials you will work on and select the blade that will cut that material. It would also be acceptable for the "softer" material. However, if you lot program to cut the softer material more than the harder one, select the diamond saw that can cutting that material instead.

- Look at the manufacturer's' labeling as they bespeak the recommended materials for each bract. Likewise look for a reputable manufacturer that offers warranties and service when using their products.

- For higher cutting speed, consider using the turbo rim design with faster cooling technology, as more h2o flows through the blade. Turbo rims can cutting granite, rustic tiles, clinker, refractory, slate and porcelain tile.

Below you will find a clarification of the most used types of blades in the market place and their applications. I will too make the case for each type of the RUBI tile saw blades.

How to Cut Porcelain Tiles?

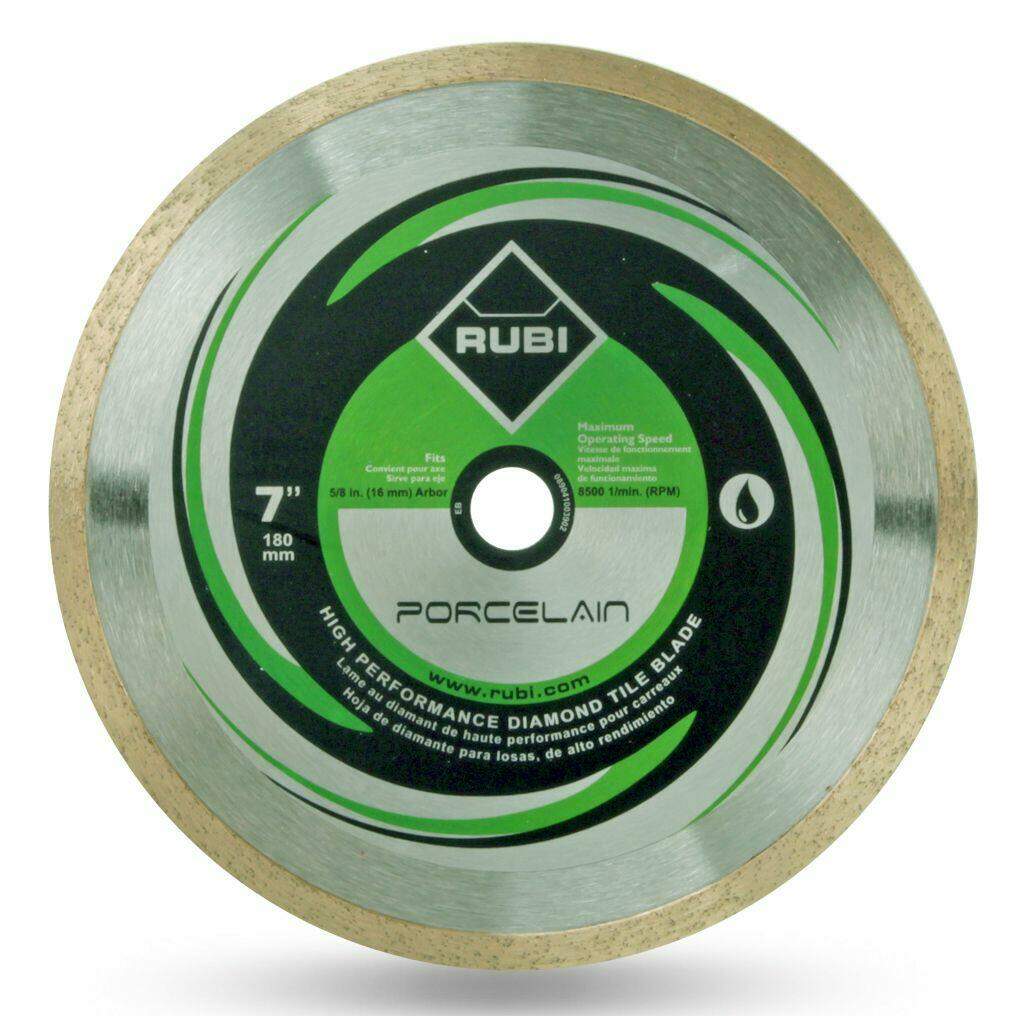

One of the all-time diamond saw blades that RUBI offers to cut porcelain tiles is the Premium Arrowhead. RUBI has ii types of blades used on porcelain tiles both of them offering loftier speed and smashing precision. Both types, the Premium Arrowhead and the Porcelain blade, are available in four ½, seven and x inches. The smaller sizes are recommended for both wet and dry applications. The thicker the diamond blade, the wider the cut volition be, then make certain you lot sympathize the needs for your project and other factors such as cut speed, depth of the cut (that's why in that location are different diameters) and feed rate.

The Premium Arrowhead designed provides for stronger bonding between the diamond rim and the steel cadre. This RUBI model is not recommended for miter cuts, although it is a fantastic tool for using it in very difficult porcelain tiles.

The Premium Arrowhead designed provides for stronger bonding between the diamond rim and the steel cadre. This RUBI model is not recommended for miter cuts, although it is a fantastic tool for using it in very difficult porcelain tiles.

If you are not careful enough, you might end up chipping the surface of a porcelain tile. These are some of the best recommendations y'all can follow when using your moisture saw to cutting porcelain tile.

If you are not careful enough, you might end up chipping the surface of a porcelain tile. These are some of the best recommendations y'all can follow when using your moisture saw to cutting porcelain tile.

- Mark the tile with a wax pencil

- When possible use a wet saw tabular array cutter, only nosotros know that it is not always available.

- Use masking tape along the edge of the tile to reduce the gamble of chipping.

- The meridian of the tile must always make contact first with the diamond saw.

- Avoid cut all the manner through the tile thickness. Try cutting at 1/8″ depth outset and so follow with a second cut only at present cutting total depth.

- Do not strength the tile as the blade is cutting information technology to preclude damaging the tile. The importance of this is to cutting the tile at a very deadening speed to minimize chipping.

- Burn marks on the side of the tile mean you are going likewise fast. A second pass of the diamond saw blade might remove additional cutting imperfection. Also recall that the perimeter grout tin can hide of them too.

Drinking glass Cutting Diamond Blades

The well-nigh important rule when cutting drinking glass is to use the right blade. RUBI offers 2 sizes of a glass diamond blade: 7 and 10 inch, along with a fantastic continuous blazon of blade. It is of import to prepare the diamond saw, because when the blade is new, they are not "gear up" to cutting drinking glass. For such reasons RUBI's cleaning block is another important tool that you need to accept. When the blade revives, the cut is cleaner and neater, reducing the possibility of damaging the glass tile. After using the cleaning block, the blade will regain the right speed and minimize the vibration of the disc.

Recommended Diamond Blades for Natural Rock

RUBI Tools offers both a vii-inch and a 10-inch diamond blade for natural stone. Natural stone is one of those materials that you don't desire to cut using tile snips. Stone tiles are hard thus the importance of using the right blade for the cut. Diamond blades are the all-time option for natural stone as it can add together the required speed and toughness to cutting through stone without damaging it. Cutting natural stones requires patience and working with the tile saw at a very depression speed. Due to the toughness of the textile, the blade might overheat if pushed besides hard or if there is not plenty flow of h2o to cool down the blade. Exist very careful when cutting natural rock and utilise the correct pressure and speed to avoid fractures.

RUBI's VIPER Diamond Blade – The "All Star" Blade

RUBI's VIPER Diamond Blade – The "All Star" Blade

Let's say that you accept done your enquiry and still not sure which blade to utilise. We all have gone through that. That'due south why RUBI Tools take come up with a powerful and all-purpose diamond blade: the VIPER diamond bract. The VIPER is bachelor for both dry and wet cuts, and is so powerful that reduces the vibration and the wobbling while using it. The blade used for dry out cuts is available on 4 and 4-one/2 inch diameters, while the bract for moisture cut is available as a 7, viii, x, 12 and 14 inch diameter. The VIPER is ideal to deal with very hard tiles.

Not only hard tile, it is intended for cutting granite, rustic tiles, clinker, refractory, slate and porcelain tile. Its pattern allows faster cutting and avoids many issues that other blades may present. The VIPER should be, undoubtedly, the favorite among professional tile contractors. The unique pattern on the edge of the blade enhances the diamond particles allowing a faster cut. The holes next to blade help the bract cool down to avoid overheating. If you are having bug with very hard flooring cloth, the VIPER bract is the right 1 for you.

Not only hard tile, it is intended for cutting granite, rustic tiles, clinker, refractory, slate and porcelain tile. Its pattern allows faster cutting and avoids many issues that other blades may present. The VIPER should be, undoubtedly, the favorite among professional tile contractors. The unique pattern on the edge of the blade enhances the diamond particles allowing a faster cut. The holes next to blade help the bract cool down to avoid overheating. If you are having bug with very hard flooring cloth, the VIPER bract is the right 1 for you.

Tips and Tricks When Using Diamond Blades

Hither are a few tricks that can extend the blade'due south life span and make your piece of work easier:

- There are right and wrong spinning directions. Every blade has an arrow signaling the direction of the rotation. Install the blade knowing how the blade will rotate.

- If your blade is non working properly, perhaps information technology is time to sharpen the bract's edge using a cleaning cake.

- Tiles and/or materials cut at different speed. Do not endeavour to cut tile at the same speed equally natural stone, and so forth.

- For better results, always cut tiles over a stable and clean surface.

- If your bract is bouncing, and so it is not suitable for that material. Get a different blade or endeavour a new one.

- To fix a blade, attempt cutting through a softer material that can betrayal diamond particles.

- If dry cutting, allow the blade to absurd downwardly.

- Normally, cutting with less pressure level will extend the life of your blade.

- Avert cutting large pieces of fabric or material that are too thick with simply one laissez passer of the blade.

- Watch out the speed of the blade, it must remain constant from outset to terminate. If non, and so replace the blade or apply less pressure.

- Thinner blades piece of work better is you lot are aiming for a smooth surface finish, faster cut, and better cut accuracy.

- If you see dark spots in your blade, there is non enough h2o cooling the blade or yous are going too fast.

Source: https://www.rubi.com/us/blog/rubi-diamond-blades/

0 Response to "How to Know When You Need a New Miter Saw Blade"

Postar um comentário